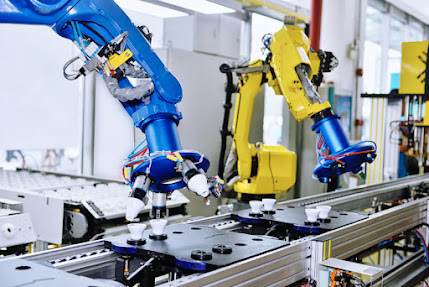

Less expensive, more competent, and more ?exible advancements are speeding up the development of completely computerized creation offices. The vital test for organizations will be concluding how best to tackle their power.

At one Fanuc plant in Oshino, Japan, modern robots produce modern robots, managed by a staff of just four laborers for each shift. In a Philips plant delivering electric razors in the Netherlands, robots dwarf the nine creation laborers by more than 14 to 1. Camera creator Canon started transitioning away from human work at a few of its production lines in 2013.

This "lights out" creation idea — where fabricating exercises and material streams are dealt with completely naturally — is turning into an inexorably normal quality of present day producing. To a limited extent, the new influx of robotization will be driven by exactly the same things that initial carried mechanical technology and mechanization into the work environment: to liberate human specialists from messy, dull, or perilous positions; to work on quality by disposing of blunders and decreasing inconstancy; and to reduce producing expenses by supplanting progressively costly individuals with ever-less expensive machines. The present most progressive mechanization frameworks have extra capacities, in any case, empowering their utilization in conditions that poor person been appropriate for robotization up to now and permitting the catch of completely new wellsprings of significant worth in assembling.

Falling robot costs

As robot creation has expanded, costs have gone down. Throughout recent years, the typical robot cost has fallen by half in genuine terms, and, surprisingly, further comparative with work costs . As interest from arising economies empowers the development of robots to move to cheaper districts, they are probably going to become less expensive still.

Open ability

Individuals with the abilities expected to configuration, introduce, work, and keep up with mechanical creation frameworks are turning out to be all the more broadly accessible, as well. Mechanical technology engineers were once interesting and costly subject matter experts. Today, these subjects are broadly shown in schools and universities all over the planet, either in committed courses or as a feature of more broad training on assembling advances or designing plan for fabricate. The accessibility of programming, for example, reproduction bundles and disconnected programming frameworks that can test automated applications, has decreased designing time and chance. It's additionally made the assignment of programming robots more straightforward and less expensive.

Simplicity of incorporation

Progresses in registering power, programming advancement procedures, and systems administration advances have made gathering, introducing, and keeping up with robots quicker and less exorbitant than previously. For instance, while sensors and actuators once must be exclusively associated with robot regulators with devoted wiring through terminal racks, connectors, and intersection boxes, they currently use plug-and-play advancements in what parts can be associated utilizing less difficult organization wiring. The parts will distinguish themselves naturally to the control framework, enormously diminishing arrangement time. These sensors and actuators can likewise screen themselves and report their status to the control framework, to help process control and gather information for upkeep, and for nonstop improvement and investigating purposes. Different norms and organization innovations make it likewise direct to connect robots to more extensive creation frameworks.

New capacities

Robots are getting more astute, as well. Where early robots aimlessly followed a similar way, and later cycles utilized lasers or vision frameworks to identify the direction of parts and materials, the most recent ages of robots can coordinate data from various sensors and adjust their developments progressively. This permits them, for instance, to utilize force criticism to impersonate the expertise of a skilled worker in crushing, deburring, or cleaning applications. They can likewise utilize all the more remarkable PC innovation and large information style examination. For example, they can utilize ghostly investigation to check the nature of a weld as it is being made, decisively diminishing how much postmanufacture examination required.

Robots take on new jobs

Today, these variables are assisting with supporting robot reception in the sorts of utilization they as of now succeed at today: dreary, high-volume creation exercises. As the expense and intricacy of robotizing errands with robots goes down, almost certainly, the sorts of organizations previously utilizing robots will utilize much a greater amount of them. In the following five to a decade, be that as it may, we expect a more principal change in the sorts of undertakings for which robots become both in fact and monetarily suitable. Here are a few models.

Low-volume creation

The inborn adaptability of a gadget that can be modified rapidly and effectively will enormously lessen the times a robot needs to rehash a given undertaking to legitimize the expense of purchasing and dispatching it. This will bring down the edge of volume and pursue robots an affordable decision for specialty undertakings, where yearly volumes are estimated during the tens or hundreds as opposed to in the large numbers or many thousands. It will likewise make them reasonable for organizations working with little cluster sizes and critical item assortment. For instance, flex track items presently utilized in aviation can "creep" on a fuselage utilizing vision to coordinate their work. The expense reserve funds presented by this sort of low-volume mechanization will help various sorts of associations: little organizations will actually want to get to robot innovation interestingly, and bigger ones could build the assortment of their item contributions.

Arising advances are probably going to improve on robot programming much further. While it is now normal to show robots by driving them through a progression of developments, for instance, quickly further developing voice-acknowledgment innovation implies it might before long be feasible to give them verbal guidelines, as well.

Profoundly factor assignments

Progresses in man-made brainpower and sensor advancements will permit robots to adapt to a far more noteworthy level of errand to-task fluctuation. The capacity to adjust their activities in light of changes in their current circumstance will set out open doors for mechanization in regions like the handling of horticultural items, where there is huge part-to-part fluctuation. In Japan, preliminaries have previously shown the way that robots can slice the time expected to reap strawberries by up to 40 percent, utilizing a stereoscopic imaging framework to recognize the area of products of the soil its readiness.

These equivalent capacities will likewise drive quality upgrades in all areas. Robots will actually want to make up for likely quality issues during assembling. Models here incorporate adjusting the power used to collect two sections in view of the layered contrasts between them, or choosing and joining different measured parts to accomplish the right last aspects.

Robot-produced information, and the high level examination strategies to utilize them, will likewise be valuable in figuring out the basic drivers of value. If higher-than-ordinary force necessities during gathering end up being related with untimely item disappointments in the field, for instance, fabricating cycles can be adjusted to recognize and fix such issues during creation.

Complex assignments

While the present universally useful robots have some control over their development to inside 0.10 millimeters, a few current designs of robots have repeatable precision of 0.02 millimeters. People in the future are probably going to offer much more elevated levels of accuracy. Such capacities will permit them to take part in progressively sensitive undertakings, for example, stringing needles or gathering exceptionally complex electronic gadgets. Robots are additionally turning out to be better planned, with the accessibility of regulators that can all the while drive many tomahawks, permitting different robots to cooperate on a similar errand.

At last, high level sensor advances, and the PC power expected to examine the information from those sensors, will permit robots to take on undertakings like cutting gemstones that recently required profoundly talented craftspeople. Similar advancements might try and allow exercises that isn't possible by any means today: for instance, changing the thickness or arrangement of coatings continuously as they are applied to make up for deviations in the fundamental material, or "painting" electronic circuits on the outer layer of designs.

Working close by individuals

Organizations will likewise have undeniably more opportunity to conclude which errands to robotize with robots and which to physically lead. High level wellbeing frameworks mean robots can take up new situations close to their human associates. In the event that sensors demonstrate the gamble of an impact with an administrator, the robot will consequently dial back or change its way to stay away from it. This innovation allows the utilization of robots for individual undertakings on in any case manual mechanical production systems. What's more, the expulsion of wellbeing walls and interlocks mean lower costs — a shelter for more modest organizations. The capacity to put robots and individuals one next to the other and to redistribute errands between them likewise helps efficiency, since it permits organizations to rebalance creation lines as request varies.

Robots that can work securely in vicinity to individuals will likewise prepare for applications from the firmly controlled climate of the manufacturing plant floor. Web retailers and strategies organizations are now taking on types of mechanical mechanization in their stockrooms. Envision the efficiency benefits accessible to a bundle messenger, however, if an installed robot could presort bundles in the conveyance vehicle between drops.

Dexterous creation frameworks

Computerization frameworks are turning out to be progressively adaptable and clever, adjusting their way of behaving naturally to expand yield or limit cost per unit. Master frameworks utilized in drink filling and pressing lines can naturally change the speed of the entire presentation line to suit whichever action is the basic imperative for a given group. In auto creation, master frameworks can naturally